Why engineers use JunYi for silicone rubber molding

Ready to get your silicone rubber mold?

Silicone Compression Molding

Compression molding has been used to mold rubber parts since the beginning of the rubber manufacturing industry. It is one of the oldest methods still used to mold rubber parts. JunYi is a silicone molding company that has utilized compression molding since the year 2010. Silicone compression molding offers JunYi's customers an effective and efficient way to manufacture low-volume production parts.

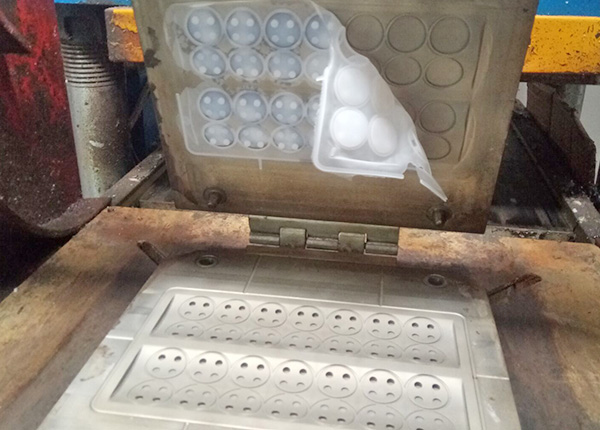

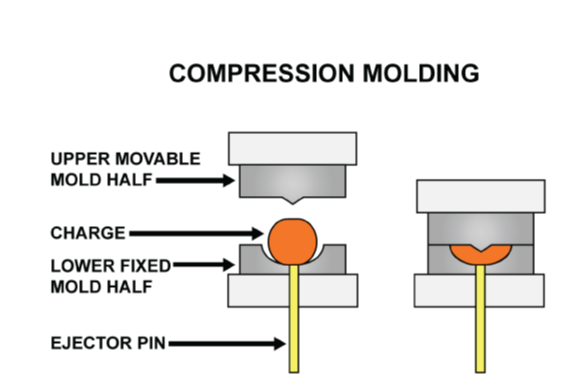

The compression molding process is quite simple when compared to injection molding, transfer molding or extrusion molding. JunYi will manufacture a compression mold tool which requires CNC machining and hand polishing. Once the tool is ready for engineering samples, then each plate is loaded with liquid silicone rubber. Simple part designs typically only require a two plate mold, which includes a cavity side and a core side. After the material is loaded, the mold plates are assembled and inserted into a compression molding press between the two platens. Next the press is clamped to a set pressure to produce high quality parts. Heat and pressure are applied for a given amount of time allowing the liquid silicone to spread throughout the mold cavity and cure. Then pressure is released from the press, which then opens and the compression mold is removed. Then the plates are separated using hand tools and finally the silicone part is removed. This completes a normal compression molding cycle for a simple silicone part design.

JunYi has a range of differently sized compression molding presses in both our controlled environment room and on our production floor. This ensures that we can run small to large sized parts and single cavity molds, as well as multi-cavity ones in either space. If needed, we can easily configure our molding equipment and space to meet our customers' demand for production.

Our silicone rubber molding Service

We are pleased to share decades of experience and silicone molding know-how with our customers to ensure that they receive only the highest quality silicone molded prototypes and production parts.

| Name | Description |

|---|---|

| Minimum order quantity | 100 runs |

| Mold material | Tool Steel P20 |

| Mold storage | Minimum 2 years |

| Mold lead time | Typically 1-2 weeks |

| Quality assurance | Inspection reports included, full dimensional report and material certifications available upon request. |

| Design verification program | Similar to First Article Inspection, you will receive 2 sets of parts upon the machining of the mold to test fit before continuing with full production. |

| Mold remachining | We can remachine the molds should any changes be required, changes to be reviewed on a case by case basis. |

| Reorders | Unit price is based on the quantity required for the reorder with an additional set up fee of $80- $200. |

| Additional technical support | Dedicated JunYi Mechanical Engineer for technical support. |