Why engineers use JunYi for Extrusion + CNC Machining

Instant quoting & quick DFM

We are able to send you a quote 20 minutes or less after received your RFQ on working time for prototypes that less than 10 items on request. If we got RFQ before 10a.m, we'll provide quotes at the same day for prototypes. Normally quotes for tools and production will be provided within 48hours. If you have a plan to get your project move forward, we'd like to provide a quick DFM for your reference free of charge.

Readily available capacity

Benefit from our high precision equipments, comprehensive manufacturing capability and dedicated team, we are standing by your side to get your projects move forward quickly.

Quality & reliability

Dedicated JunYi team to ensure your parts consistently meet your quality expectations. We also offer phone, email and chat support for any concerns or questions you may have.

Ready to start Extrusion + CNC Machining?

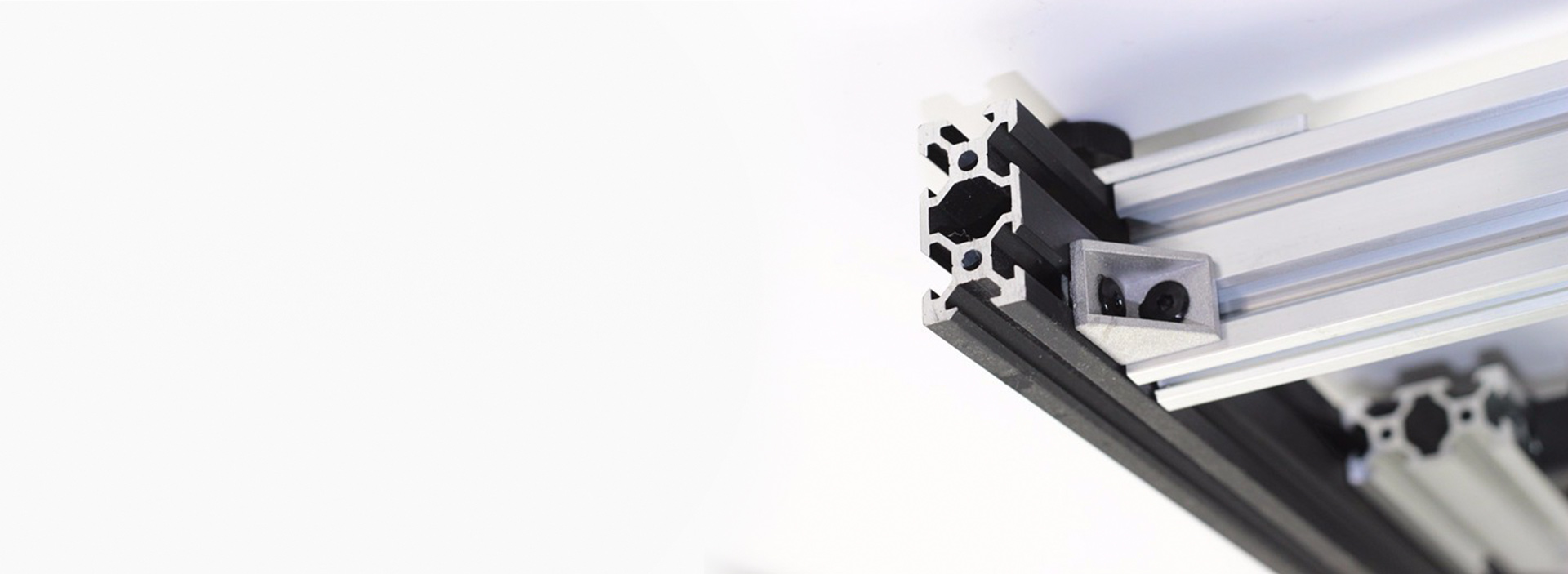

Our Extrusion + CNC Machining

Custom Finishes

Aluminum extruded parts can be produced with exceptionally smooth surfaces and accept a variety of paints and plating finishes.

Part Production

The simplicity of the extrusion process yields 80-90% lower tooling costs that other processes like injection molding or die casting.

Precision

Modern extrusion presses and processes produce close tolerance extruded shapes that are durable and dimensionally stable.exExtrusion Processes

-

Hot Extrusion

Hot extrusion is done above the material's recrystallization temperature to keep the material from work hardening. -

Cold Extrusion

Cold extrusion is done at or near room temperature. The advantages of cold extrusion versus hot extrusion are higher strength, closer tolerances, and the lack of oxidation. -

Friction Extrusion

With friction extrusion, force is applied to push the charge against a die.