Silicone Rubber Molding: The brief introduction and engineering guide

Ready to get your silicone rubber mold?

Wall Thickness The wall thickness does not have to be uniform because the material does not sink like thermoplastic. Very thin walls are possible with silicone molding even down to 0.005 in / 0.127mm.

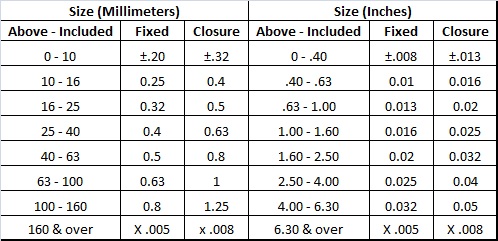

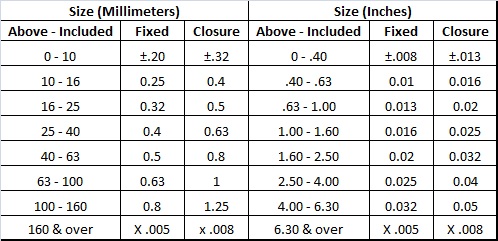

Tolerances and Molded Part Shrinkage Tolerances for molded parts are directly related to part shrinkage. The best practice is to build a test shrinkage mold of the part and use data to build prototype or production mold. The variations between lots of Liquid Silicone can be little, compared to thermoplastics, therefore, tolerances can be a lot closer. We typically apply RMA A3 "Commercial" tolerances, however, due to our precision machining capabilities and silicone's ability to replicate microscopic features, tighter tolerances are possible, including tolerances as tight as +/- .002 in / .050 mm are attainable.

Tolerances and Molded Part Shrinkage Tolerances for molded parts are directly related to part shrinkage. The best practice is to build a test shrinkage mold of the part and use data to build prototype or production mold. The variations between lots of Liquid Silicone can be little, compared to thermoplastics, therefore, tolerances can be a lot closer. We typically apply RMA A3 "Commercial" tolerances, however, due to our precision machining capabilities and silicone's ability to replicate microscopic features, tighter tolerances are possible, including tolerances as tight as +/- .002 in / .050 mm are attainable.

If a fit tolerance is required it is best to fit the silicone molded part to the fitted part, since measurement of a silicone molded part requires non contact measurement and measurements under .002 in / .05 mm are very difficult. Tolerances: Dimensional Tolerance Table for Molded Rubber Products Shrinkage – Occurs during molding and post curing or until fully cross-linked.

Shrinkage – Occurs during molding and post curing or until fully cross-linked.

– Varies by the manufacture and product range from .025 per inch.

– Typical shrinkage is between 1% and 5% depending upon material

– Check with your material supplier regarding shrink percentage of the material you plan to work with

Coefficient of Thermal Expansion Silicone has a high thermal expansion coefficient and can be used as a temperature activation method or sensor in the design. This expansion is an advantage for sealing applications. The coefficient of volumetric thermal expansion for all silicone rubber products is in the range of 5.9 to 7.9 x 10-4-4/°C. The linear coefficient of thermal expansion is roughly one-third of the volumetric coefficient of thermal expansion, and can be used to calculate the total linear thermal expansion of a rubber part over a temperature range.

Example: If the volumetric coefficient of thermal expansion is 5.9 x 10-4/°C and the temperature span is 150°C, the total linear expansion of a part one-inch long would be … (5.9 x 10-4/°C)/3 x 150 °C x 1 in. = 0.0295 in. Thermal and Electrical Conductivity Thermal values for any thermal insulating material usually range from 0.330 to 0.515 x 10-³ g-cal/sec/cm²/cm/°C. An electrical value for any electrical insulating material is the value of dielectric strength changes combined with the thickness of the test specimen. For a 10-mil sample silicone rubber, 1000 volts per mil is quite normal.

Silicone is a good insulator and can be compounded to be a good thermal conductor as well by adding certain fillers. A good example of this would be silver.

Optical Properties Silicone is now being used to replace plastic and glass optical lens. Some Silicone refractive index can equal that of glass (1.53), and are optically clear. It is even possible to have higher surface finishes than typical glass lens at a reduced cost.

The advantages for using Silicone over plastic are UV aging, ability to operate at high temperatures, and the wider spectrum of transmission compared to acrylic and polycarbonate.

If a fit tolerance is required it is best to fit the silicone molded part to the fitted part, since measurement of a silicone molded part requires non contact measurement and measurements under .002 in / .05 mm are very difficult. Tolerances: Dimensional Tolerance Table for Molded Rubber Products

– Varies by the manufacture and product range from .025 per inch.

– Typical shrinkage is between 1% and 5% depending upon material

– Check with your material supplier regarding shrink percentage of the material you plan to work with

Coefficient of Thermal Expansion Silicone has a high thermal expansion coefficient and can be used as a temperature activation method or sensor in the design. This expansion is an advantage for sealing applications. The coefficient of volumetric thermal expansion for all silicone rubber products is in the range of 5.9 to 7.9 x 10-4-4/°C. The linear coefficient of thermal expansion is roughly one-third of the volumetric coefficient of thermal expansion, and can be used to calculate the total linear thermal expansion of a rubber part over a temperature range.

Example: If the volumetric coefficient of thermal expansion is 5.9 x 10-4/°C and the temperature span is 150°C, the total linear expansion of a part one-inch long would be … (5.9 x 10-4/°C)/3 x 150 °C x 1 in. = 0.0295 in. Thermal and Electrical Conductivity Thermal values for any thermal insulating material usually range from 0.330 to 0.515 x 10-³ g-cal/sec/cm²/cm/°C. An electrical value for any electrical insulating material is the value of dielectric strength changes combined with the thickness of the test specimen. For a 10-mil sample silicone rubber, 1000 volts per mil is quite normal.

Silicone is a good insulator and can be compounded to be a good thermal conductor as well by adding certain fillers. A good example of this would be silver.

Optical Properties Silicone is now being used to replace plastic and glass optical lens. Some Silicone refractive index can equal that of glass (1.53), and are optically clear. It is even possible to have higher surface finishes than typical glass lens at a reduced cost.

The advantages for using Silicone over plastic are UV aging, ability to operate at high temperatures, and the wider spectrum of transmission compared to acrylic and polycarbonate.