Available materials for CNC machining

Here is a list of our standard CNC machining materials available through our online platform.

| Plastics | Aluminum | Stainless steel | Other steels | Other metal |

|---|---|---|---|---|

| ABS | 6061-T6 | 303 | Mild steel 1018 | Brass C360 |

| Nylon 6 | 6082 | 304 | Mild steel 1045 | Copper C101 |

| POM (Delrin/Acetal) | 7075 | 316 | Mild steel A36 | Copper C110 |

| PC (Polycarbonate) | 5083 | 2205 Duplex | Alloy steel 4140 | Titanium Grade 2 |

| PVC | 5052 | 17-4 | Alloy steel 4340 | Zinc alloy |

| HDPE | 6063-T5 | 420 | Tool steel O1 | Magnesium alloy AZ91D |

| PTFE (Teflon) | 7050 | Tool Steel A2 | ||

| PEEK | Tool Steel D2 | |||

| Nylon 15%GF/30%GF | Tool Steel S7 | |||

| Acrylic (PMMA) |

Available surface finishes for CNC machining

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

| Name | Description | |

|---|---|---|

|

As Machined (standard) | ~125 RA µin (3.2 RA µm). Minor tool marks will be visible on the part. |

|

Smoothed | Parts are machined at a lower feed rate in order to achieve a surface roughness of ~62.5 RA µin (1.6 RA µm). Surface roughness can be decreased up to ~32 RA µin (0.8RAµm) upon request. |

|

Bead Blasted | Bead blasting adds a uniform matte or satin surface finish on a machined part, removing all tool marks. Mainly used for aesthetic purposes. |

|

Anodized Clear or Color (type II) | Anodizing adds a thin, hard, non-conductive ceramic coating on the surface of aluminum parts, increasing their corrosion and wear resistance. Available in a variety of colors. |

|

Anodized Hardcoat (type III) | Hardcoat anodizing produces a thicker ceramic coating providing excellent corrosion and wear resistance. for functional applications. |

|

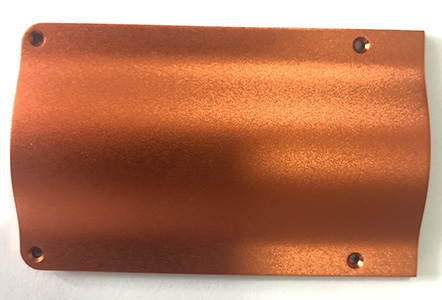

Powder Coated | Powder coating adds a thin layer of strong, wear and corrosion resistant protective polymer paint on the surface of a part. Available in a large range of colors. |

|

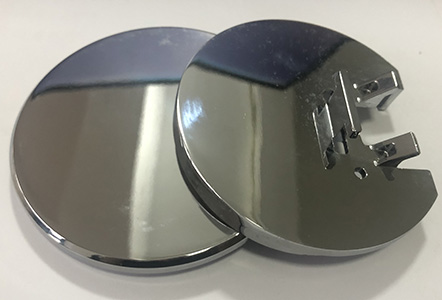

Electropolished | Electropolishing is an electrochemical process used to polish, passivate and deburr metal parts. It is useful to reduce surface surface roughness. |

|

Black oxide | Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection. |

|

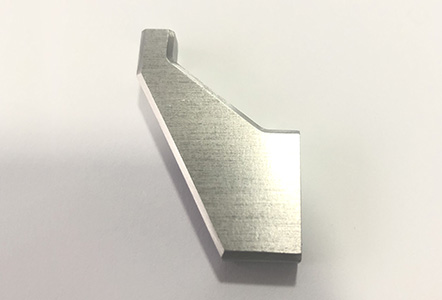

Brushing | Brushing is produced by polishing the metal with grit resulting in a unidirectional satin finish. |