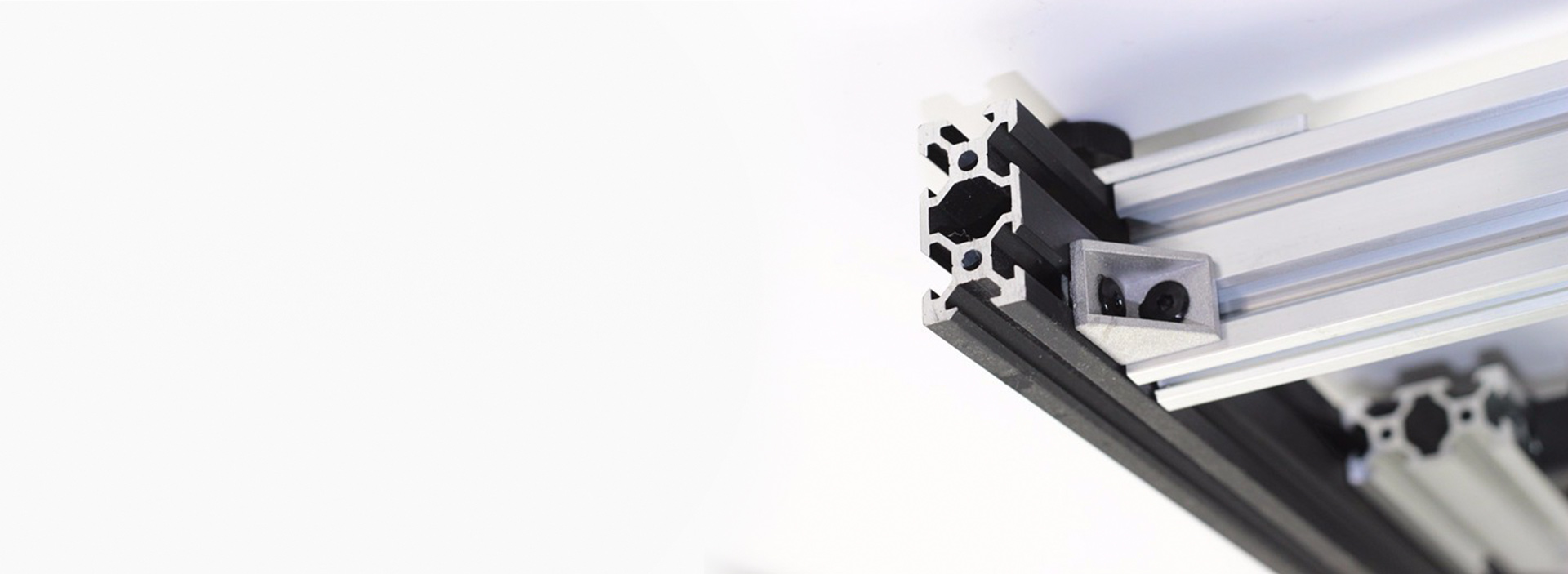

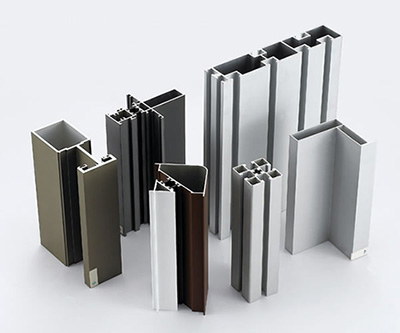

Extrusion Materials

In the Hot Extrusion Process, different products are manufactured using various materials that are also called Extrusion Materials. Mainly, the extrusion materials that are used include Aluminium, and Copper along with their alloys.

| Extrusion Metals | Products Developed |

| Aluminum Alloys | Pipe, Wire, Rods, Bars, Tubes, Heat sink |

| Copper | Pipe, Wire, Rods, Bars, Tubes, and Welding Electrodes |

| Lead and Tin | Pipes, Wire, Tubes, and Cable Sheathing |

| Magnesium | Aircraft Parts and Nuclear Industry Parts |

| Zinc | Rods, Bars, Tubes, Hardware Components, Fitting, and Handrails |

| Steel | Rods and Tracks |

| Titanium | Aircraft Components including Seat Tracks, Engine Rings, and other structural parts |

Extrusion Finishes

- Anodyzing (Type II Or Type III)

- Powder Coating

- Wet Painting

- Chemical Film

- Custom Finishes

Anodyzing (Type II Or Type III)

Extrusions can be anodized before they are cut and are limited by the length of the anodizing line. Type II anodizing creates a corrosion-resistant oxide finish on aluminum parts. Parts can be anodized in different colors—clear, black, red, and gold are most common. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. Anodized coatings are not electrically conductive.