Available materials for Sheet metal fabrication

Here is a list of our standard Sheet metal fabrication materials available through our online platform.

| Aluminum | Stainless steel | Other steels | Other metal |

|---|---|---|---|

| 5052 | 303 | Mild steel 1018 | Brass C360 |

| 3003 | 304 | Mild steel 1045 | Copper C101 |

| 6061-T6 | 316/316L | Mild steel A36 | Copper C110 |

| 6082 | 17-4 | Alloy steel 4140 | Copper7521 |

| 7075 | 420 | Alloy steel 4340 | Brass C260 |

| 5083 | Nickel | ||

Available surface finishes for Sheet metal fabrication

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

| Name | Description | |

|---|---|---|

|

As Cut (Natural) | Parts are cut or machined from the machine. Minor tool marks will be visible on the part. It can be deburred upon request. |

|

Bead Blasted / Sand Blasted | Bead blasting adds a uniform matte or satin surface finish on a machined part, removing all tool marks. Mainly used for aesthetic purposes. |

|

Anodized Clear or Color (type II) | Anodizing adds a thin, hard, non-conductive ceramic coating on the surface of aluminum parts, increasing their corrosion and wear resistance. Available in a variety of colors. |

|

Powder Coated | Powder coating adds a thin layer of strong, wear and corrosion resistant protective polymer paint on the surface of a part. Available in a large range of colors. |

|

Black Oxide | Black Oxide is a conversion coating used to improve corrosion resistance and minimize light reflection. |

|

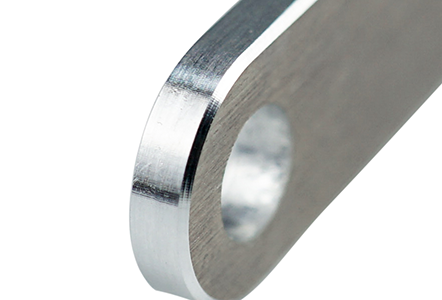

Brushing | Brushing is produced by polishing the metal with grit resulting in a unidirectional satin finish. |

|

Galvanizing | Galvanizing is primarily used to change the surface properties of an object (such as abrasion and wear resistance, corrosion protection, lubricity, aesthetic qualities) |

|

Silk-Screening | Silk screens can be used to add personality and style to most metal surfaces. While silk screening may seem like a daunting task, it is actually fairly simple. With a few basic printing tools you can create any number of one-of-a-kind designs. |

|

Wet Painting | Wet painting is the traditional (although technologized) process of applying liquid paint to a metal product for finishing. Most sheet metal fabrication processes will use a spray, pump, or pressurized vessel to deliver the wet paint evenly. |

|

E-Coating (High & Low) | E-coating is an immersion wet paint finishing process that uses electrical current to attract the paint product to a metal surface. It has superior corrosion resistance and environmentally friendly. |